The fundamental principle behind the development of Helmerding plants and machines is a modular focus that incorporates defined interfaces. This applies equally to the presses, coil feeding systems, transfer systems and to the peripheral system components such as tool changers and robotics. This allows the plant and machinery manufacturer to ensure that customer-specific requirements, starting with their tooling concepts, can be more rapidly integrated – and configured – into the execution systems for presses and accessories using in-house, standardised, incrementally expandable modules. The customer benefits are particularly apparent in the reduced development costs, our proven-quality press systems that consolidate many years of experience, our proven product creation process and shorter lead times.

Helmerding has been manufacturing its products according to this principle since 1945, thereby guaranteeing the reliable and high performance interaction between press and peripheral. Our final output is the benefit we offer our customers.

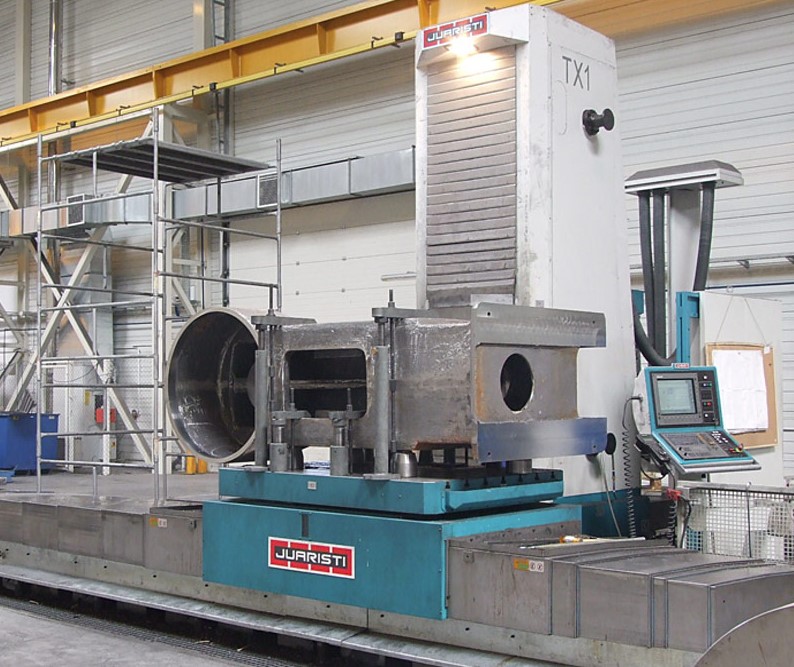

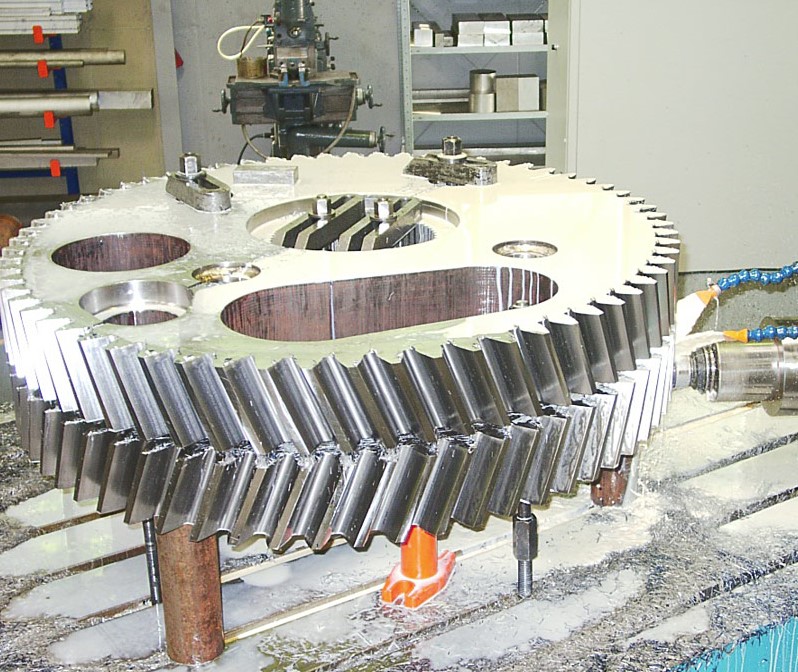

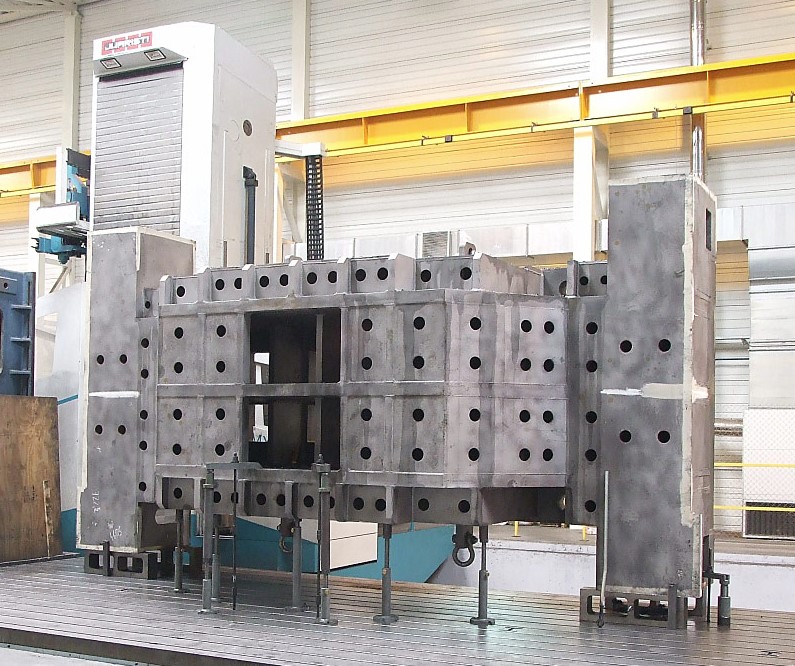

Helmerding guarantees precision and quality through certified business processes and by producing a high percentage of components in-house. The good infrastructure in terms of buildings, processing machines and systems for supporting our work processes is a further key quality element.